Spray Foam Insulation: How It Works and Key Considerations

Spray foam insulation is a versatile method for improving a building’s thermal performance and air-tightness. Applied as a liquid that expands and hardens, it fills gaps, reduces drafts, and can improve energy efficiency when installed correctly. This article explains how spray foam works, the main types, installation considerations, and practical cost guidance to help property owners and contractors assess whether it suits their needs.

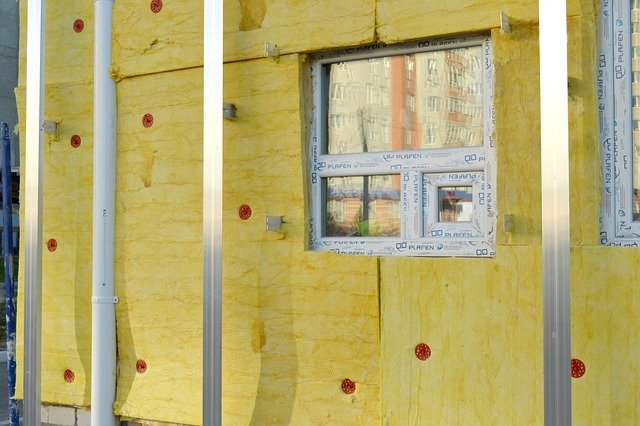

What is spray foam insulation?

Spray foam is a foam material — typically polyurethane or a similar polymer — that is sprayed onto surfaces and expands to form an insulating layer. There are two main categories: open-cell and closed-cell. Open-cell foam is less dense and more flexible, providing good sound absorption and breathability, while closed-cell foam is denser, more rigid, and offers higher thermal resistance per thickness as well as moisture resistance. Both types create an air barrier in addition to insulation.

Benefits and limitations

Spray foam can reduce air leakage, improve thermal comfort, and sometimes allow for thinner insulation layers compared with traditional products. It is useful for irregular cavities, rim joists, and around penetrations where batts would be difficult to install. Limitations include higher upfront cost, the need for professional installation in many cases, and care with ventilation and moisture management in some assemblies. Material selection and correct thickness are important to avoid trapping moisture or creating other unintended consequences.

Installation process and preparation

Proper installation begins with surface preparation: cleaning, drying, and ensuring substrates are suitable for adhesion. Installers use two-component systems mixed at the spray gun; temperature and humidity at the time of application affect expansion and curing. Protective equipment and containment may be needed to protect occupants from fumes during application. After curing, excess foam is trimmed and, if required, covered with a thermal or fire-resistant board or plasterboard to meet building regulations. A trained installer will assess appropriate thickness and safety measures for the specific project.

Cost considerations and performance trade-offs

When evaluating spray foam, balance initial cost against potential energy savings and space constraints. Closed-cell foam typically offers higher R-value per inch and acts as a vapour retarder, which can be useful in certain retrofit and new-build scenarios; open-cell foam is generally cheaper and better for sound attenuation. Consider long-term performance, product warranties, and installer credentials. Also factor in any additional finishing or protective materials required to meet local building codes or fire-safety standards.

The following table gives an illustrative comparison of common spray foam options and how they are typically offered by manufacturers or local installers. Costs are broad estimates and can vary with project size, location, and site conditions.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Open-cell spray foam (general insulation) | Local certified installers / manufacturers | Est. £15–£35 per m² for typical residential applications (depending on thickness and site conditions) |

| Closed-cell spray foam (high-density, moisture-resistant) | Local certified installers / manufacturers | Est. £30–£70 per m² for typical residential applications (depending on thickness and site conditions) |

| Professional site assessment and preparation | Insulation contractors / energy assessors | Est. £150–£500 for assessments, may be included in quotes for larger installs |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Practical tips for choosing an installer

Select an installer with proven experience in spray foam systems and appropriate certifications or trade memberships. Ask for references, examples of completed projects, and a written scope that details foam type, target thickness, expected R-value, surface preparation, and any required aftercare or finishing work. Confirm how the installer addresses ventilation and moisture management and whether they provide a workmanship warranty. Local services may vary in their specialisms; for instance, some focus on cavity fill retrofits while others concentrate on new-build roof conversions.

Conclusion

Spray foam insulation can be an effective solution for improving thermal performance and airtightness where its properties match the building’s needs. Assess the type of foam, installation quality, regulatory requirements, and whole-building moisture and ventilation strategies before proceeding. Because costs and product options vary by location and project specifics, obtain multiple detailed quotes and, where appropriate, consult a qualified building professional to ensure the chosen approach is compatible with the building fabric and long-term performance goals.